Single Point Gap Frame - CP Series

The press frame is constructed of heavily reinforced 1020 steel, fully stress relieved. The crankshaft is machined from a 1045 steel forging. This gives the press low deflection and high rigidity for long life; not only for the press, but for your dies as well.

Features and Dimensions

Standard

|

Options (call for a complete list)

|

| Model | CP-35 |

CP-60 |

CP-80 |

CP-110 |

CP-160 |

CP-200 |

CP-250 |

| A | 46.5" |

50.5" |

55" |

60" |

66.5" |

75.5" |

80.5" |

| B | 47.5" |

63" |

67.5" |

75" |

82" |

93.5" |

106" |

| C | 99" |

101.5" |

116.5" |

131.5" |

140" |

153" |

160.5" |

| D | 30" |

31.5" |

33" |

35.5" |

35.5" |

37.5" |

40" |

| Main Motor | 5 HP |

7.5 HP |

10 HP |

15 HP |

20 HP |

25 HP |

30 HP |

| Weight Lb | 6700 |

10000 |

15000 |

25000 |

37500 |

51500 |

71500 |

Machine Specifications

| Model | CP-35 |

CP-60 |

CP-80 |

Cp-110 |

CP-160 |

CP-200 |

CP-250 |

| Capacity (US tons) | 39 |

66 |

88 |

121 |

176 |

220 |

276 |

| Tonnage Rating Point | .120" |

.160" |

.200" |

.240" |

.280" |

.280" |

.320" |

| Stroke Length | 2.8" |

3.9" |

5.1" |

5.9" |

7.9" |

9.8" |

9.8" |

| SPM (Variable) | 60-100 |

50-90 |

40-80 |

35-60 |

30-50 |

25-45 |

25-40 |

| Shut Height | 9.9" |

11.8" |

13.8" |

15.7" |

17.7" |

19.7" |

21.7" |

| Slide Adjustment | 2.2" |

2.8" |

3.1" |

3.5" |

4" |

4.3" |

4.7" |

| Bolster Area (L-R x F-B) |

27.5" x 15.5" |

33" x 19.7" |

39.5" x 23.6" |

43.5" x 27.6" |

51.2" x 31.5" |

57" x 33.5" |

63" x 35.5" |

| Bolster Thickness | 2.8" |

3.2" |

4.8" |

5.9" |

7.1" |

7.9" |

8.3" |

| Slide Area (L-R x F-B) |

16.1" x 11.8" |

18.9" x 16.5" |

21.7" x 19.7" |

33.5" x 19.7" |

39.4" x 27.6" |

45.3" x 29.5" |

49.2" x 31.5" |

| Throat Depth | 8.5" |

10.3" |

12.4" |

14.6" |

16.5" |

17.5" |

18.3" |

| Main Motor | 5 HP |

7.5 HP |

10 HP |

15 HP |

20 HP |

25 HP |

30 HP |

| Slide Adjust Motor | .3 HP |

.5 HP |

.7 HP |

1 HP |

1.5 HP |

1.5 HP |

2 HP |

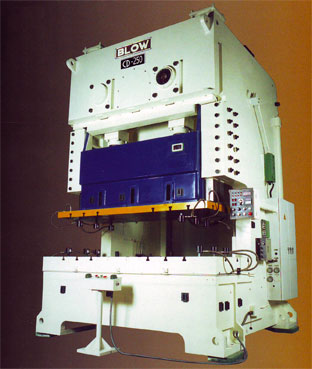

Two Point Gap Frame - CD Series

This press gives you a broader working space. The rigid frame and six-point gibbing guarantees precision through the stroke. This model ensures increased productivity and cost reduction by using less floor space and by utilizing progressive manufacturing.

Features and Dimensions

Standard

|

Options (call for a complete list)

|

| Model | CD-80 |

CD-110 |

CD-160 |

CD-200 |

CD-250 |

| A | 61" |

84" |

98.5" |

113" |

116.5" |

| B | 68.55" |

86.5" |

92.5" |

97" |

106" |

| C | 108" |

145" |

149" |

153" |

171" |

| D | 35" |

36" |

37.5" |

39" |

42" |

| Main Motor | 10 HP |

15 HP |

20 HP |

25 HP |

30 HP |

| Weight Lb | 22500 |

42000 |

60500 |

73000 |

95500 |

Machine Specifications

| Model | CD-80 |

CD-110 |

CD-160 |

CD-200 |

CD-250 |

| Capacity (US tons) | 88 |

121 |

176 |

220 |

276 |

| Tonnage Rating Point | .160" |

.200" |

.240" |

.280" |

.320" |

| Stroke Length | 5.5" |

7.1" |

7.8" |

9.8" |

11" |

| SPM (Variable) | 40-80 |

35-60 |

30-50 |

25-45 |

25-40 |

| Shut Height | 13.8" |

15.7" |

17.7" |

19.6" |

21.6" |

| Slide Adjustment | 3.1" |

3.5" |

4" |

4.7" |

4.7" |

| Bolster Area (L-R x F-B) | 43.7" x 17.7" |

73" x 25.6" |

86.6" x 29.5" |

98.5" x 33.5" |

106" x 39.5" |

| Bolster Thickness | 4.4" |

4.8" |

5.9" |

6.7" |

8.3" |

| Slide Area (L-R x F-B) | 39.4" x 11.8" |

65" x 23.6" |

78.7" x 23.6" |

88.6" x 25.6" |

94.5" x 31.5" |

| Throat Depth | 9.8" |

13.8" |

15.8" |

17.8" |

20.8" |

| Main Motor | 10 HP |

15 HP |

20 HP |

25 HP |

30 HP |

| Slide Adjust Motor | 1 HP |

1 HP |

1 HP |

2 HP |

5 HP |